INTEGRATED MONITORING SOFTWARE

CUT THE COST WITH REAL-TIME VISIBILITY TO YOUR CRITICAL SHIPMENTS

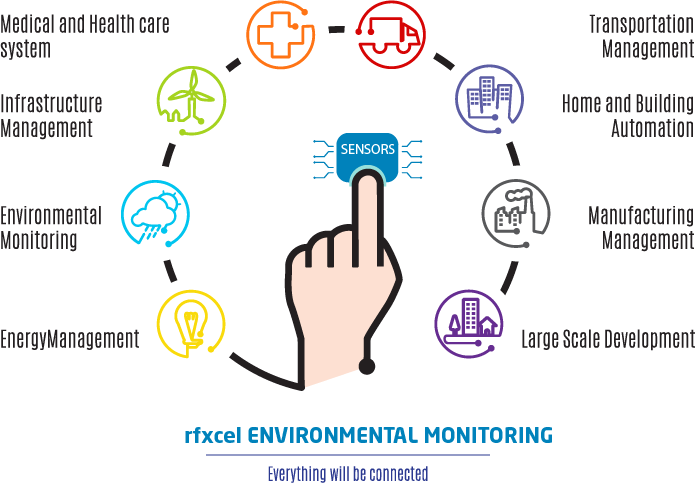

rfxcel’s Integrated Monitoring (rIM) solution, powered by Internet of Things (IoT) technologies, gathers real-time data to help streamline your supply chain, improve delivery and address compliance requirements by remotely monitoring your critical assets. Never wonder again about the status of your products or if they are being treated according to product safety regulations – track any data point with rIM.

RFXCEL INTEGRATED MONITORING FUNCTIONS

rfxcel Integrated Monitoring provides a rich set of monitoring capabilities to track a diverse set of industry needs.

The healthcare, pharmaceutical, and food and beverage industries have some of the most complex and highly regulated supply chains systems. Ensuring the safety, quality, and timely delivery of products can be a life or death concern. The costs associated with these efforts are rising and it’s becoming harder to proactively monitor the supply chain without innovation and technology. rfxcel addresses these supply chain challenges with its IoT technology for the Integrated Monitoring Software.

Based on the latest IoT technology, rfxcel enables live monitoring of products in the supply chain. With this technology, companies in any industry can now take corrective action in real time instead of discovering the issue after it is too late. The real-time nature of rIM provides the opportunity for cost savings and competitive differentiations.